Company Profile

The company was founded in 1984. Joint-stock system of enterprises, which covers an area of more than13,200 m2 and a building area of 9,800 m2, the existing staff of more than 400 people.

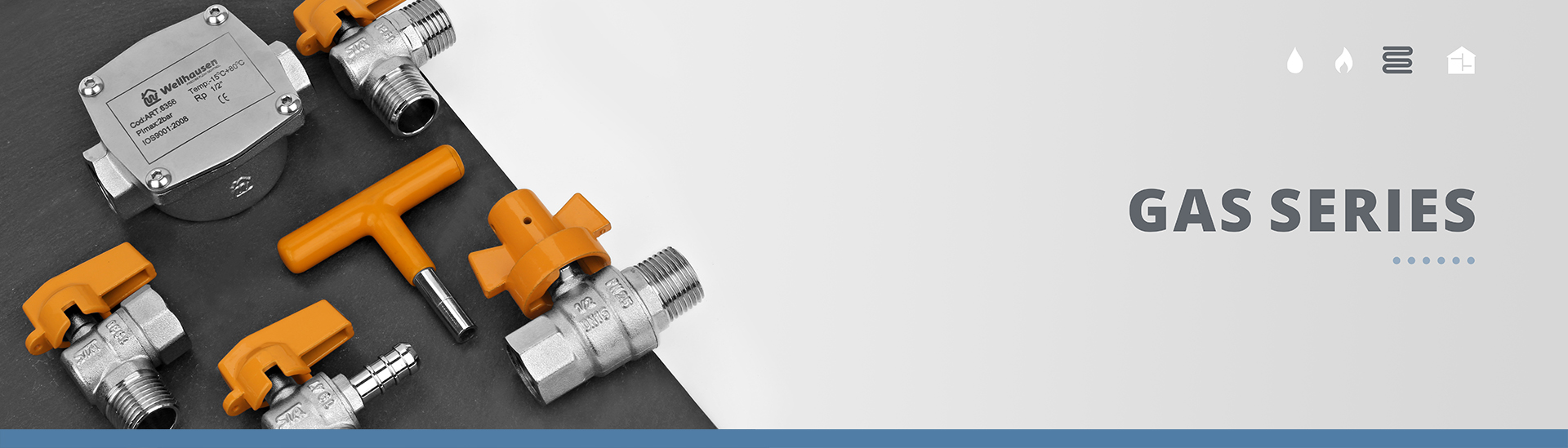

The company mainly produces ball valves, fittings, plumbing fittings, hot air valve, etc. Series of products, with brass as···

QUALITY

Sidante: dedicated first and foremost to qualityA vocation for quality and total dedication to the customer: these are the cornerstones of our mission, where the quality of the end products and the selected materials is at the centre of our entire production process.

STA company

The story of a continually evolving companyOur company was founded in 1969 in Pisogne (BS). We have always been highly aware of the needs of the community and over the years, we have become a competitive business in all plumbing and underfloor heating sectors. We are constantly committed to giving value to our human resources and we involve company personnel in all phases of the production process, in order to guarantee valid, expertly manufactured products.

AVANT-GARDE INDUSTRIAL SYSTEM

Highly automated departments and machinery with the latest technologyWe are a solid, reliable business, founded to promote the great manufacturing tradition of Made in Italy. Our industrial system winds its way through well-structured, avant-garde departments, in which all our production phases have been automated.

COMISA WORLDWIDE

STA, the flagship of global Made in ItalyFrom the very beginning, we have had an international vision, which has launched us way beyond our local area and enabled us to compare with other giants in the sector, in order to continue the professional development and expansion of our company. We export our end products throughout 53 countries.

RENEWABLE ENERGIES

STA looks to the future with respectWe believe there is a cleaner way to protect the environment. We have always worked on the principle of preserving a natural balance, by constantly investing in renewable energy. This philosophy is mirrored in our structures, equipped with low environmental impact systems, and in our products with the aim to optimise energy consumption.

THE PRODUCTION PROCESS

We are qualified in the production of plumbing products and of underfloor heating and cooling systems.

Moulding

Hot moulding enables the modelling of raw materials. The new generation presses, which can reach a maximum pressure of 500,000 kg/cm², produce the components of our products.

Mechanical processing

The Transfer machines department, fully automated with anthropomorphic robots, is the result of a continuous technological innovation. Our advanced machines are able to perform multi-sided machining and CNC machines.

Assembly

The assembly line is equipped with the most modern, automated robots. Our highly qualified technicians check all the production process to guarantee a unique, manufactured product.

Quality control

Our team of qualified technicians scrupulously checks every step of the production process, without neglecting any detail, in order to guarantee the customer the highest quality of product performance.

THE PRODUCTION PROCESS

STA Fully implement of lean production andERP management,we are focusing on the lefficient operation,we meet demand of icustomers,create value for customers.

product design

Have professional designers in the industry.

Warehouse storage

Fast and specific guaranteed delivery.